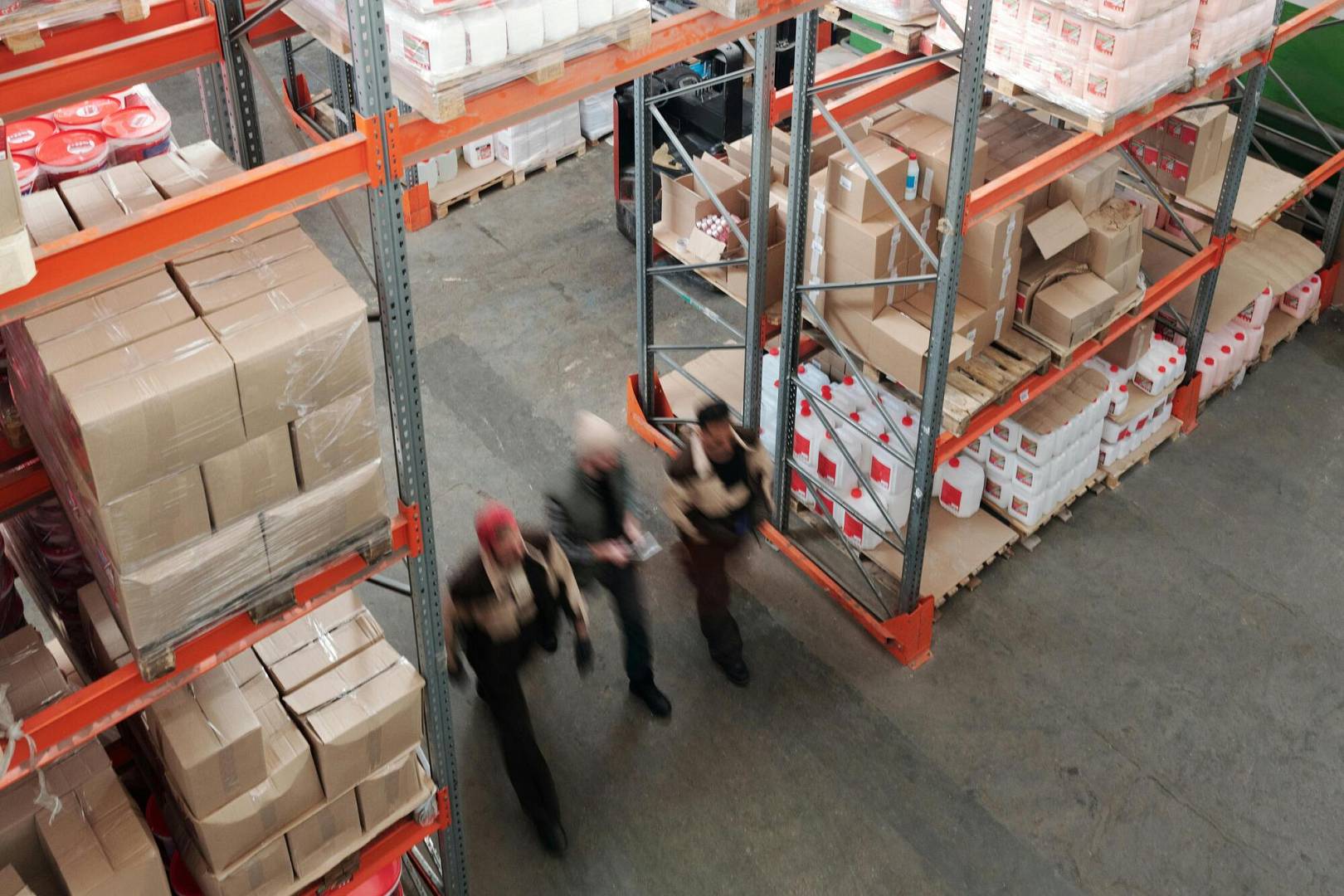

Warehouses operate at pace. Tight deadlines, high stock volumes, and constant movement of handling equipment all place pressure on storage systems. While racking is built to handle heavy loads, it is not immune to damage, and overlooking maintenance can lead to serious safety and operational issues.

Making racking condition part of routine warehouse management helps reduce risk and maintain efficiency.

Everyday Causes of Racking Damage

In busy warehouse environments, damage often occurs gradually. Forklift contact, misaligned pallets, and overloading can all weaken racking components over time. Uprights and lower beams are particularly vulnerable in narrow aisles or high throughput areas.

Because damage is not always obvious, it can be missed during daily operations. This is why regular inspections and prompt racking repairs are essential to maintaining safe storage.

Safety, Compliance, and Responsibility

UK warehouse operators have clear responsibilities under health and safety legislation to provide safe working environments. Damaged racking increases the risk of collapse, injury, and product loss.

Addressing issues through professional racking repairs helps maintain compliance and demonstrates that reasonable steps are being taken to manage risk. It also supports insurance requirements and reduces the likelihood of unplanned shutdowns following an incident.

Repairs That Support Productivity

Racking repairs are often viewed as a disruption, but in reality they help prevent far greater operational issues. Targeted repair work can restore strength and stability without the need for full system replacement.

Planned repairs reduce downtime, protect stock, and allow warehouses to continue operating efficiently. When repairs are carried out correctly, they extend the working life of existing racking and improve long term cost control.

Making Racking Care Part of Daily Operations

The most effective warehouses build racking maintenance into everyday site management. This includes training staff to report impacts, scheduling regular inspections, and acting quickly when damage is identified.

Clear repair records also support audits and provide evidence of ongoing maintenance, helping managers stay in control of compliance and safety standards.

Final Thoughts

Racking is a core part of warehouse infrastructure. Keeping it in safe working condition protects people, stock, and productivity.

By taking a proactive approach and prioritising professional racking repairs, UK warehouses can reduce risk, maintain compliance, and keep operations running smoothly even under pressure.