What Are High Voltage Power Supplies Used For?

High voltage is essential for a wide range of specialized applications, whether it’s in pharmaceutical research, modern manufacturing techniques, or scientific investigations. High voltage is necessary in both higher power systems, like electron beam welding, additive manufacturing, lithography, and ion implantation, to manipulate electrons and ions for changing the composition of the final sample. It’s also utilized in lower-power systems, including scanning electron microscopes and mass spectrometry, to generate, filter, and accelerate ions and electrons.

How Does a High-Voltage Power Supply Function?

The primary side of a conventional high voltage power supply features a DC voltage generated through rectification, filtering, and a conventional regulator. The control circuit and high-frequency switches convert this DC voltage into a high-frequency AC voltage before stepping it up with a high-voltage transformer. The transformer then outputs a voltage, which may be multiplied through several stages depending on the required output voltage (kV).

Your power supply topology will vary depending on the voltage, power, and stability requirements you specify. Achieving tighter control over the output voltages, currents, and filtering may necessitate better feedback loops.

What Is the Difference Between High Voltage and Low-Voltage Power Supplies?

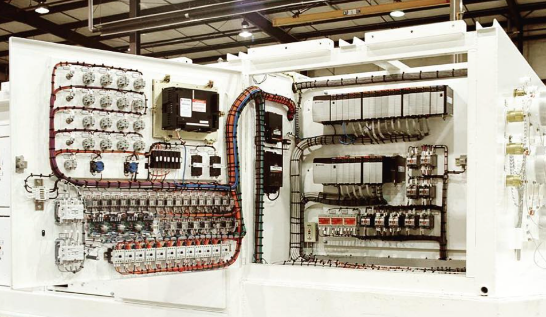

High voltage power supply units are typically more complex than low-voltage units, incorporating components such as high voltage magnetics and voltage multipliers, along with sophisticated regulation circuits. They are designed to maintain and control high stability outputs.

Low-voltage power supplies are intended for small devices, such as personal electronic gadgets or appliances that do not require high power input. Low-voltage power is both safer and less expensive to produce than high voltage.

Is High Voltage Electricity Dangerous?

Contact with high voltages capable of delivering sufficient energy can result in serious injury or even death. High voltage power supplies are engineered to prevent injuries, safeguard equipment, and prevent fires.

To protect both the equipment and the operator, it is necessary to employ overvoltage protection, short-circuit protection, current-limiting, and isolation techniques. It’s imperative to purchase a high voltage power supply from a reputable source.

How Can I Select the Best High Voltage Power Supply for My Needs?

The power and voltage requirements for your application will dictate your choice. Applications like electroporation and mass spectrometry, or using an electrostatic chuck, demand less power, while applications like e-beam welding and additive manufacturing require more power. You’ll also need to determine your ripple requirements based on your application. For performance-critical applications like mass spectrometry or SEM, ripple control is of greater importance. However, for capacitor charging, ripple is less crucial. In such cases, a faster rise time and a quicker decay are more important.

This post was written by Justin Tidd, Director at https://www.swartzengineering.com. For nearly half a century, Swartz Engineering has been at the forefront of industry safety. They are a family-owned company specializing in power distribution for the electrical industry. Our design ensures maximum flexibility for excellent reliability and a high return on investment.